| |

|

1. Tighten up your STS at Home Depot

One thing you ought to do this afternoon - if you haven't already - is get yourself a Short Throw Shifter kit. An STS, while not an item that adds unto your vehicle any amount of locomotion, adds a great degree of driving confidence and fun factor. One might even argue the STS has been clinically proven to increase shifting alacrity by some measurable statistical percentage.

While shopping for your STS you no doubt will balk at the price of the industry-leader, TWM. While TWM makes by and large the highest quality STS kits on the market (but don't tell that to the guy who was tooling along in his Genesis with his TWM kit one day when the knob & upper rod assembly literally broke off the rod, leaving him listless), they also make the most expensive one. Typically speaking the more you pay for a CNC machined component like this, the better the quality will be, unless it comes from ARK or CP-E, in which case its still kind of a crapshoot depending on who was at the wheel and if they were awake during design or procurement stages of the product development. Or if they were sober.

While even the TWM isn't perfect in terms of manufacturing tolerances, 9/10 drivers will not purchase it purely because of the price. They will go with a Ralco, Torque Solutions, or some other cheaper brand. They will then, like thousands of tuners before them, encounter the Dancing Shift Knob Effect of a low-cost STS. Not only does your shifter now feel a little imprecise and loose, but while in-gear and underway, your shift knob is vigorously masturbating against it's shift boot. This not only looks strange and evokes a deep and nauseating sense of poor workmanship, it makes you feel alot less confident in your car because, well, your shifter is jacking off right next to you.

Alot of people, including myself, have found themselves admonishing the driver of the car we're sitting in that this is just par for the course with budget shifters, and that it doesn't affect performance of the shift linkage. Technically this is true; you will be able to drive, shift gears and be a fancy bastard without obstruction or obfuscation. But you can do better.

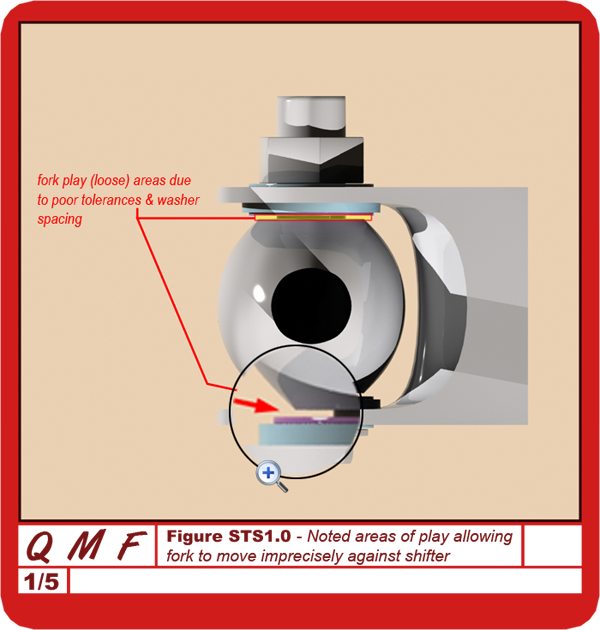

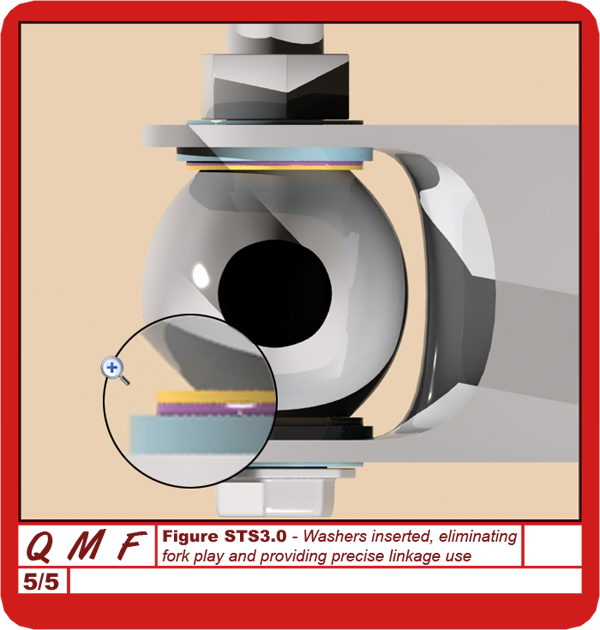

When I installed my very first Ralco STS on my own car, being the OCD Fascist that I am, I noted the poor tolerances of the shift rod's lower crossbolt linkage when installed in the fork. When in-gear, the shifter still had alot of play in it, leading to a feeling of imprecision and the dreaded DSKE.

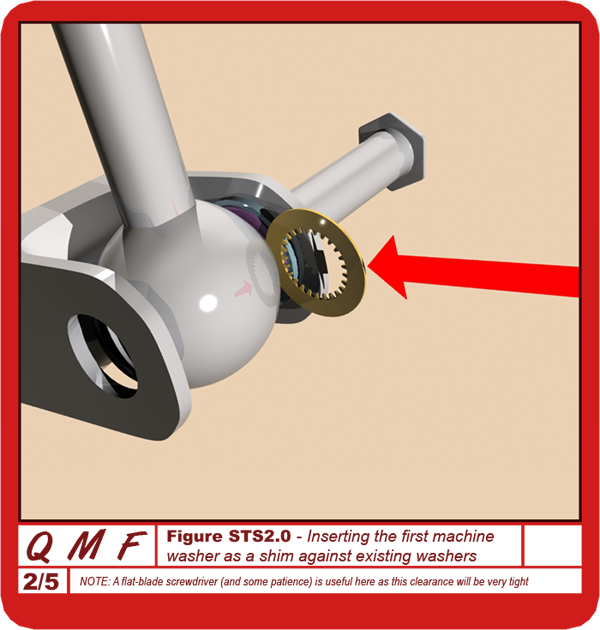

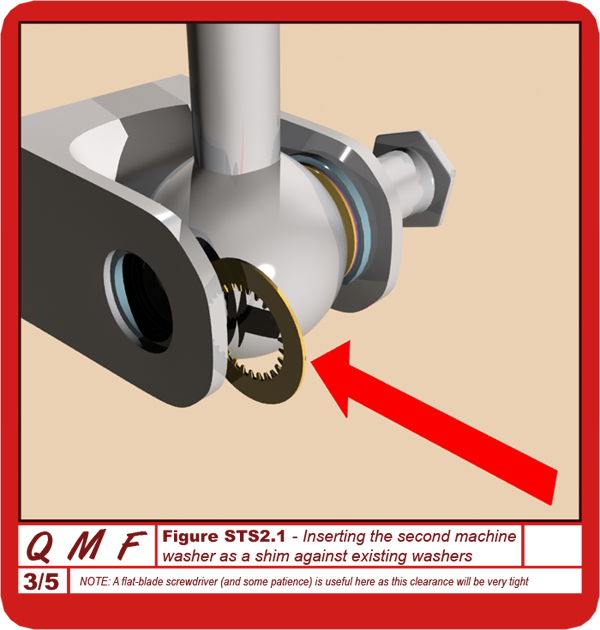

I went to work the next day as an orange, aproned taskmaster of oppressed minions (I was a department supervisor at Home Depot) and purchased a little bag of #10 toothed machine lockwashers. Not the cut lockwashers you are thinking of. Because words fail me when communicating with the general public, turn off your brain (if you were using it) and look at pictures instead.

- BEFORE YOU DO THIS GO PURCHASE A REPLACEMENT CROSS BOLT & NUT (NOT A LOCK NUT!) OF HIGH GRADE (GRADE 5-8) MATERIAL AND GET BLUE LOCTITE!

- ** YOU MAY ONLY NEED TO SHIM ONE SIDE WITH ONE WASHER DEPENDING ON YOUR PARTICULAR SHIFTER & FORK **

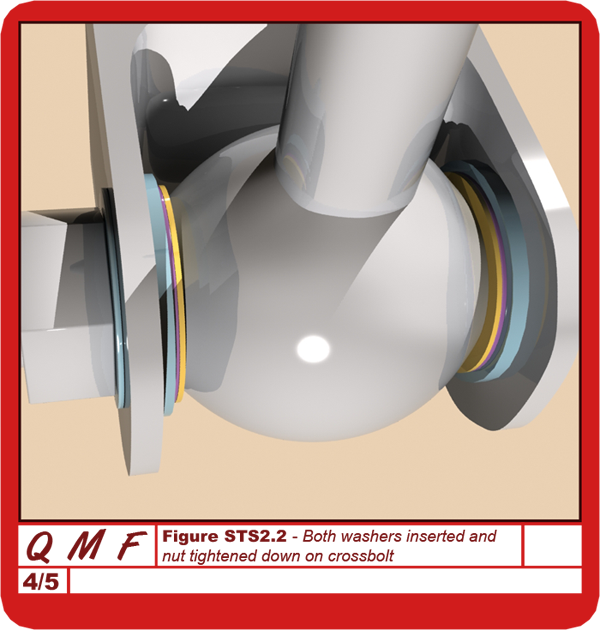

- IMAGES NOT TO SCALE / NOT ALL STS KITS WASHER SETS MAY LOOK EXACTLY THE SAME / OBVIOUSLY YOUR SHIFT ROD AND WASHERS ARE NOT BLUE OR PURPLE, THIS IS TO VISUALLY DISTINGUISH OBJECTS.

Inserting the washers is a troublesome endeavor that can be infuriating given the tightness of shoving them into the virgin fork while also keeping the other washers on one side in place and shoving the bolt through the whole assembly, twice. A flat blade screwdriver is helpful, and I've found that spinning the bolt slowly by hand as you work it against the thin machine washer to try and get the washer onto the bolt helps a bit. Also another thing that helps immensely is gently twisting the shift rod back and forth as it sits inside the fork - as you push the machine washer in - this will help you walk the washer inward so the bolt can pass through.

Once this is done and the bolt is through, I strongly advise applying a bit of blue Loctite to your nut, and tightening that son of a bitch down well. Not retarded monster assembly line robot tweaked my shit hard, but tight. Your STS kit may list a torque spec in the manual. Meet that torque number or barely exceed it. Your OEM shifter fork will deform as you tighten the nut to the crossbolt so don't go too crazy. The shift fork arm is not made of super high grade material, as you might have noticed. But it's just fine so don't go trying to make your own CNC replacement, please, it's fine.

2. Shift precisely with a tight, morally superior STS and Profit

Your STS should now no longer sexually satisfy itself while the car is in gear, and your shifting precision should inspire confidence in hitting the shift gates. Remember; it's the little things here and there - the workmanship - that sets your car aside from the average dipshit ricetool. And, better yet, you spent half the price of a TWM shifter and got one thats just as tight!

|

|

|

|